Addressing Dampness Challenges with Newton System 500

The Sofrana Building - Britomart, Auckland

SUMMARY

Situated in Auckland's Britomart, the Sofrana Building was constructed over a century ago to function as a warehouse supporting the bustling port of Auckland. To re-purpose the structure into a modern commercial building, with office and storage spaces as well as a new supermarket, it underwent a multi-million-dollar upgrade overseen by renowned Architects Peddlethorp.

THE PROJECT

As the Sofrana Building project approached completion, unexpected moisture issues arising from the basement floor slab were identified. These unforeseen dampness conditions were a result of a rise in the water table and the building's exterior undergoing excavation for structural adjustments.

As solution that was fast to install and cost effective needed to be found.

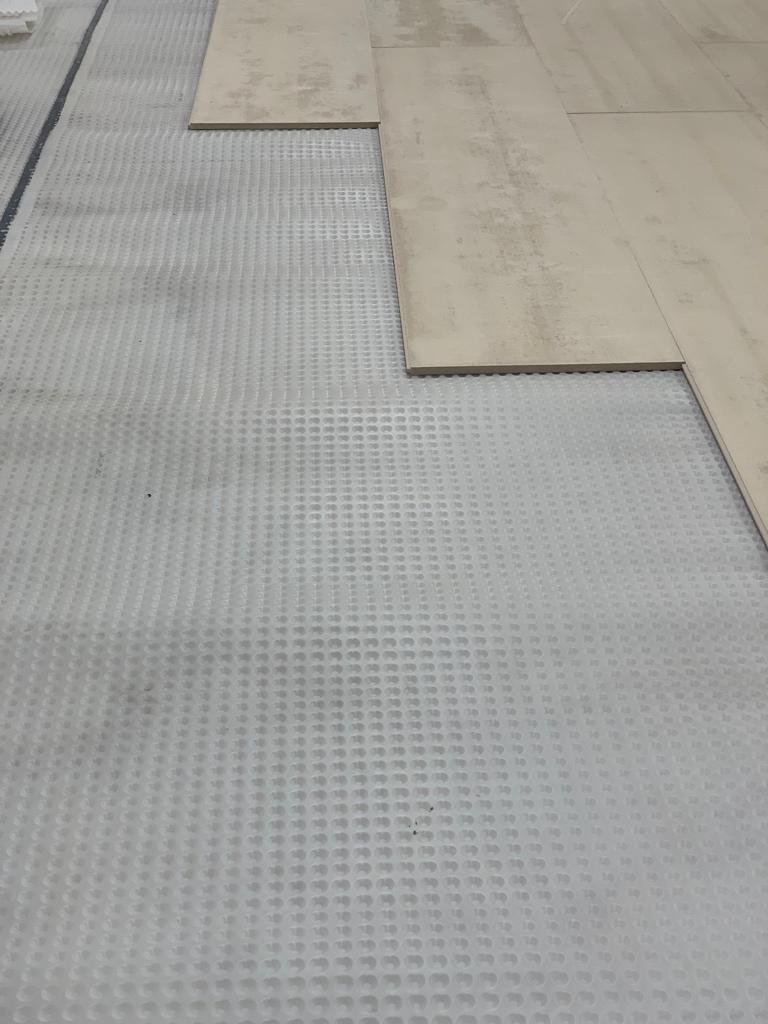

NEWTON Systems in collaboration with Newton Specialist Basement Contractor - Sansom, were brought in to provide a damp-proofing solution. To address these unforeseen dampness conditions, NEWTON's Type C damp-proof membrane was chosen as the solution - a combination of a cavity drain membrane and a vapour barrier.

THE SOLUTION

On top of supplying the client with the right solution, we needed a solution that would align with their tight deadline. Our solution was selected because the slab was so soft that no system which required bonding to the slab could be considered. Unlike traditional systems, the NEWTON 500 provides instant protection, requires minimal preparation, and does not require a drying period. This allowed for the installation of internal finishes to happen straight after our application, and our client was able to keep to their programme.

During the application process, we encountered an area where we could not increase the head height. Our solution was to slightly change our specs, excavate part of the floor slab, and prepare the substrate before putting the membrane down. We installed drainage within the thickness of the floorslab to remove any risk of water vapour rising and affecting the office space - these were connected to existing pumps on the perimeter of the building.

THE RESULT

Ultimately, this approach effectively addressed moisture issues, enabling uninterrupted operations and creating a moisture-free environment. At NEWTON Systems, our focus is on creating practical solutions, always prioritising the best outcomes for each project's durability and structural health.

“Sometimes there is only one viable option for remediation of underground basement leaks!

The Sofrana and Barrington House projects we completed for our friends at Cooper and Co in the Britomart Precinct was one of those and we successfully installed a NEWTON floor membrane system to isolate the new fitout from potential water vapour.

Heritage buildings are always full of surprises and these two delivered on that with water ingress to the basement slab only after works commenced. The slab was laid 100 years ago and was never intended to be waterproof for an office type fitout. The slab tested unbelievably low making adhesion of any screeds or coatings impossible so the NEWTON no impact to existing structure approach was perfect - Slab membrane followed by screed overlay.

Our client and their architect Peddle Thorp are thankful to Sansom and NEWTON for providing this solution to their basement issue in a timely and comprehensive manner.”